Videos

-

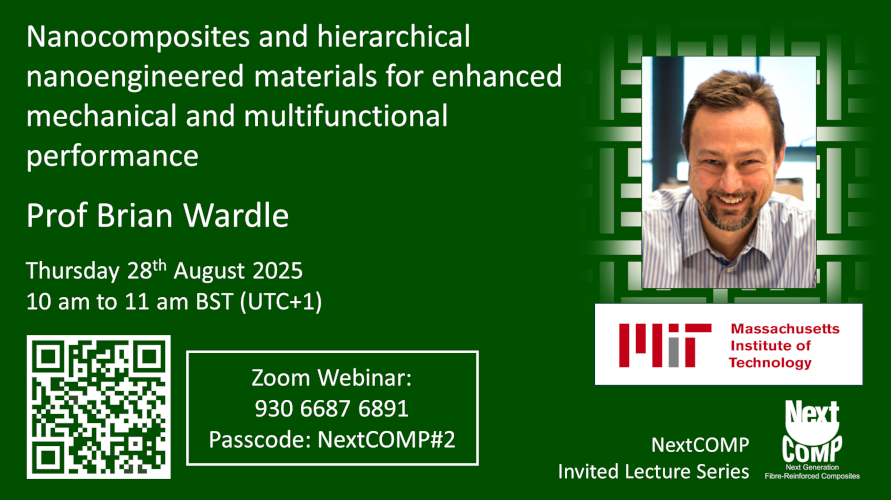

Prof Brian Wardle "Nanocomposites and hierarchical nanoengineered materials for enhanced mechanical and multifunctional performance"

= Video will be uploaded shortly =

Abstact: Bulk nanostructured materials offer tremendous opportunity for re-inventing materials, but also pose challenges both in terms of characterization, processing, design, scaling, and manufacturing. This talk will present recent work developing nanoengineered hierarchical advanced (aerospace-grade) composites with enhanced mechanical properties, with a focus recently on physics that allows imparting multifunctionality, and resulting technologies. Such hybrid nanoengineered advanced composites employ aligned nanofibers (in most of our work, aligned carbon nanotubes, A-CNTs) in several architectures to enhance bulk properties of existing aerospace-grade advanced composites. Building multifunctionality concurrent with these mechanical property improvements includes thermal and electrical conductivity tailoring for ice protection, damage sensing, and self-manufacturing, among others.

We would like to thank Brian once more for the lecture given on 28th August 2024 which was well attended in-person and virtually. For those unable to join on the day a video will be uploaded once it has been edited.

-

The cradle test: A new experiment to characterise the compression response of pultruded rods

To announce the release of "The cradle test: A new experiment to characterise the compression response of pultruded rods" in Composites Part A a short video of the test has been released by Dr Gustavo Quino. This work is the result of years of experimental development in the NextCOMP project, and from Imperial MSc student Chuo Zhao. The paper introduces a new method that simplifies specimen preparation and test setup compared to conventional direct compression tests, while mitigating stress concentrations, ensuring consistent compressive failure within the gauge length. It utilises full-field strain measurements to accurately reconstruct stress-strain curves, providing deeper insight into failure mechanisms and material performance.

Video by Gustavo and the Team is available on YouTube (0NWWrRlvFpM) 00:47 min

-

Show & Tell: Materials & Manufacturing with Milo and Emile

NextCOMP members Prof Milo Shaffer and Prof Emile Greenhalgh presented at the Materials & Manufacturing Show and Tell Series - Innovate UK Business Connect on the 16th July 2025. Emile presented research related to the Advances in Structural Energy Storage and the Aspiration for Massless Energy, and Milo presented Fibre Composites Under Compression: Opportunities from the NextCOMP Project.

The ‘Show and Tell’ series is specifically for academics who have innovative technology, and who are looking to scale-up or commercialise this through collaboration and partnerships. This is part of the Innovate UK’s Materials and Manufacturing Vision 2050 and the opportunities that lie ahead for the UK Materials and Manufacturing sectors and net zero future.

If you missed these talks they were recorded and are available via the UKRI website, or directly on Vimeo (1106051395) 32:10 min.

-

Arrest of unstable compressive cracks in fibre-reinforced polymers using ply discontinuities

A short video which demonstrates the improvements made through introducing ply discontinuities in a carbon fibre reinforced composite compared to a similar baseline composite.

-

Bristol’s HyPower Team - Inspiration from Space Sponge and competing in the European Rocketry Competition

Bristol’s HyPower Team and members of the Bristol SEDS competed in the European Rocketry Competition in Ponte de Sor, Portugal (November 2024). Their rocket featured novel lattice structure coupling based on the skeleton of a sea sponge or ‘space sponge’ taking inspiration from the natural world. This work was part of the EPSRC Centre for Doctoral Training Centre in Composites Science, Engineering and Manufacturing at Bristol Composites Institute (BCI) Design, Build and Test Project. Supported by BCI staff Dr Laura Rhian Pickard, and Dr Steve Bullock, who sat down for an interview by EttoCraft (@ettocraft) on just how the HyPower Bristol Team managed to get to the launch pad in just one year!

-

Bio-Inspired Lattice Structure, Design, Build and Test Project 2023-2024

In 2023-2024, the EPSRC Centre for Doctoral Training Centre in Composites Science, Engineering and Manufacturing at Bristol Composites Institute (BCI) Design, Build and Test Student Project was focused on the challenged to develop a bio-inspired lattice structure within a rocket interstage fairing. The goal was to demonstrate potential mass and performance benefits offered by this nature-inspired design strategy with help from NextCOMP members. NextCOMP BCI members who supported this course and are featured in the video are Dr Laura Rhian Pickard, Prof Richard Trask, Ian Lee, Prof Ian Hamerton, Prof Stephen Eichhorn, and Lucas Lu.

-

Dr Pierre-Yves Mechin "Compressive strength performance exploration on thick composites structures for high performance racing yachts"

= Video will be uploaded shortly =

Abstract: A long-term collaboration between University of South Brittany (IRDL), Dassault Systémes & marine engineering eco-system in Lorient has been established for the past 12 years with positive collaboration and results. Racing yachts are designed with dominant use of composites materials with significant anisotropy in layups and large thicknesses and high stiffness (HM400 or higher). For foils, mast & hulls, composites are often in compression (static & fatigue). The compressive strength is therefore a major topic to explore and a key parameter for performance (weight vs. stiffness). The purpose of the talk is to give an overview of the compressive strength studies & results performed with multiscale analysis considering constituents, process. This was done with a double work of experiments & numerical analysis to understand the mechanism and validate observed trends. Experiments were conducted with different resins, fibres, stackings, manufacturing process to understand the mechanism, compare materials to propose new epoxy resins and fibres combinations to increase the compressive strength. The fact that racing boats are not much defined with standard materials offer a large range of configurations to explore. Numerical studies were done to qualify an analytical model which qualify the compressive strength as a structural property, not a material value. The model was first used to get explanation on trends and more recently proposed for a general validation. The combination of CATIA & Abaqus technologies as part of the 3DEXPERIENCE Platform allow to explore the effect of the manufacturing through generation of RVE models with random fibres arrangement and waviness.

We would like to thank Pierre once more for the lecture given on 26th September 2024 which was well atteneded in-person and virually as part of our Next Generation Fibre-Reinforced Composites (NextCOMP) Invited Lecture Seminar Series. For those unable to join on the day a video will be uploaded once it has been edited.

-

Prof Kristofer Gamstedt "How do trees become strong in compression?"

= Video will be uploaded shortly =

Abstract: Fibre composites have seen an outstanding development during the last 50 years. These materials bear many resemblances with wood; being fibrous, composed of complementary constituents, anisotropic and light-weight. Clearly wood materials, just like unidirectional composites, are very strong in tension in the fibre direction, but significantly weaker in compression. In this presentation, we illustrate some of the approaches utilised by trees to compensate for the relatively weak compressive properties. These include beneficial residual stresses, a hierarchical structure for crack arrest, formation of reaction wood tissues in compression, and counteracting the weaker compressive strength with high tensile strength material in other parts of the tree. Some of these mechanisms could perhaps be exploited to a larger extend in the design of composite materials and components.

We would like to thank Kristofer once more for the lecture given on 14th August 2024 which was well atteneded in-person and virually. For those unable to join on the day a video will be uploaded once it has been edited.

-

The Great Exhibition Road Festival 2024 - Day 1 video snapshop

Dave Anthony featured in a video short for the first day of the Great Exhibition Road Festival from the weekends activites over the 15th and 16th June 2024.

Originally posted on Instagram 15th June 2024 by @imperialcollege and @exrdfestival

The recorded event is available on YouTube (SNDV1_cYV3A) 0:55 min

-

Dr Ioannis Katsivalis "Mechanical characterisation of ultra-thin tow-based discontinuous composites"

= Video will be uploaded shortly =

Abstract: A new class of composite materials which have gained significant popularity and represent an attractive alternative to Quasi-Isotropic (QI) laminates are the so-called Tow-Based Discontinuous Composites (TBDCs). These bio-inspired composite materials are manufactured by chopping continuous prepreg tapes and randomly distributing them, effectively creating a high-performance Sheet Moulding Compound (SMC) material. The random tape distribution generates in-plane isotropy, while the use of very low tape thicknesses (below 50 µm) reduces resin pockets and increases the attainable fibre volume fractions. Using thin tapes also shifts the dominant damage mechanisms, effectively eliminating transverse tape fracture and promoting tape pull-out instead. In addition, TBDCs display increased manufacturability and reduced costs and therefore expand the design space significantly. This presentation aims to provide an overview of the experimental work conducted on the TBDC material including tensile testing, fatigue characterisation, notch sensitivity analysis, bond evaluation, and compressive testing.

We would like to thank Ioannis once more for the lecture given on 7th June 2024 which was well atteneded as part of our Next Generation Fibre-Reinforced Composites (NextCOMP) Invited Lecture Seminar Series. For those unable to join on the day a video will be uploaded once it has been edited.

-

Cameron Woodgate "Compressive single fibre micromechanical analysts via in-situ Raman spectroscopy"

Cameron Woodgate showcased the work carried out during his PhD at the Bristol Composites Institute Doctoral Research Symposium 2024 held on the 26th March 2024.

The recorded event is available on YouTube (RGpl8ld_GZ0) 4:57 min

-

Aree Tongloet "A study of factors controlling the compressive behaviours of hybrid composites"

Aree Tongloet showcased the work carried out during her PhD at the Bristol Composites Institute Doctoral Research Symposium 2024 held on the 26th March 2024.

The recorded event is available on YouTube (dexCgZKyooU) 4:43 min

-

Next generation composites for high-performance applications with Dimitrios Bikos

Dr Dimitrios Bikos talks about research into next generation fibre reinforced composite materials, an area of development of particular interest for the transport industry as part of a series of Mechanics of Materials (MoM) Podcasts with Dr Michael Cornish. Dimitris is NextCOMP Team member and is in the Mechanical Engineering Department at Imperial College London, in his MoM podcast he covers diverse areas of interest from the microstructure and properties of chocolate, composite materials, and efficient modelling methodology!

It's great to hear from Dimitris and about his interests and expertise, and his insight into working in multidisciplinary Team.

The Podcast is available on YouTube (h_kDqlEiWrg), Spotify, or Apple Podcasts, 10:04 min. The transcript of the MoM Podcast Episode 4 Dimitrios Bikos is also available (pdf, 123 KB).

-

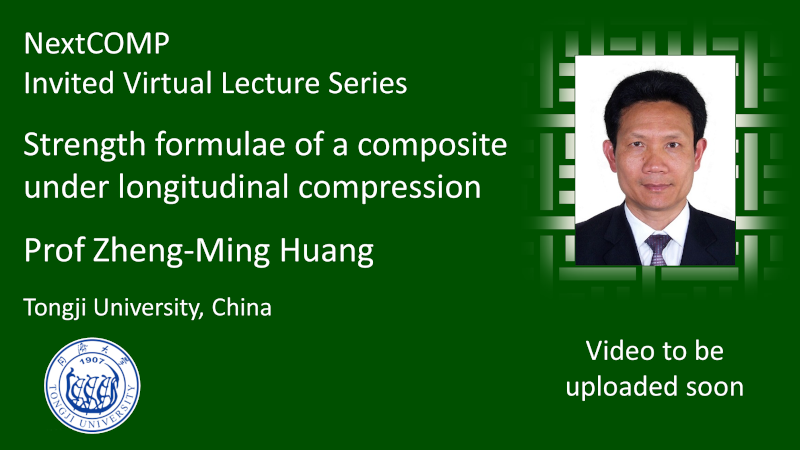

Prof Zheng-Ming Huang "Strength formulae of a composite under longitudinal compression"

= Video will be uploaded shortly =

Abstract: In this talk, I will firstly present an analytical approach to the failures and strengths of a unidirectional (UD) composite under longitudinal compression. Only limited, if not the minimum, input data are required, all of which except for the initial fiber misalignment angle can be measured in advance and following existing standards. The longitudinally dominated load is decomposed into axial, shear and transverse stress components in the misaligned coordinate system. The axial component will cause the fiber to fail whereas the other mainly the shear components will bring the matrix to fail. Whichever occurs the first corresponds to the longitudinal compressive strength. If the fiber’s failure takes place ahead of the matrix’s one, the composite attains the highest compressive strength. Otherwise, a kinking failure is assumed and the compressive strength can be much lower than an expectation. Two issues are critical for achieving the compressive strength evaluation. One is the misalignment angle increment assumed in accordance with the application of the shear component, and the other is the conversion of the homogenized internal stresses of the matrix into the true values. Bridging Model and the matrix true stress theory are the fundamental tools to have achieved the purpose. Then, I will highlight an analyzing procedure for the compressive strength prediction of any fibrous composite. The analysis is begun by subdividing the fibrous composite into a series of slides, each of which contains at most one straight fiber or fiber yarn segment. The latter can be considered as a UD composite in its local coordinate system. The overall true stresses of the fiber and matrix in the fibrous composite are assembled from those of all the slides, based on which the failure detections can be carried out individually for the fiber and matrix. The smallest failure load is defined as the ultimate compressive strength of the fibrous composite.

Bio: Dr. Zheng-Ming Huang got an MS degree in solid mechanics in 1983 from Huazhong University of Science & Technology in China, and a PhD degree in materials engineering in 1999 from National University of Singapore. He was awarded a Cheung Kong Scholars Professor at Tongji University by the Ministry of Education of China in 2002. He has established a number of unique mechanics theories for composites, including a unified elastic-inelastic constitutive theory – Bridging Model, the matrix true stress theory, the interlaminar matrix stress modification method, and the incremental constitutive model for rubber-like elasticity. Based on these theories, a variety of composite failures including interface debonding and laminate delamination has been efficiently addressed with inputs almost all measurable upon existing standards and with no iteration. He has authored or co-authored more than 210 peer reviewed journal papers, 4 books, 9 book chapters and 18 patents. One of his papers has been cited more than 7100 times in Web of Science.

We would like to thank Zheng-Ming once more for the lecture given on 15th April 2024 which was well atteneded as part of our Next Generation Fibre-Reinforced Composites (NextCOMP) Invited Virtual Seminar Series. For those unable to join on the day a video will be uploaded once it has been edited.

Prof Zheng-Ming Huang has also provided his presentation slides (pdf, 48 MB) and calculations spreadsheet (xlsx, 216 KB) for public use with a CC BY-NC-SA license.

-

Design, Build and Test Project 2022-2023

The Design, Build and Test programme is a chance for students to have a taster of the things to come in a PhD as part of their studies in a stand alone project. A look back to 2022-2023 Cohort video featuring Joe Rifai where the challenge was to design/make/test a wing spoiler deployed through sequential buckling rather than a conventional actuator.

-

Design, Build and Test Project 2021-2022

A number of NextCOMP PhD students have cut their teeth in the world of composites in the Design, Build and Test programme as part of their studies at the University of Bristol. A retrospective of the 2022-2023 Cohort (and before the Bristol Composites Institute rebrand of ACCIS, Advanced Composites Collaboration for Innovation and Science) video featuring Ian Lee and Eleni Georgiou where the challenge was to design/make/test composite box-beam suitable for a unmanned aerial vehicle tapered wing with a load carrying capacity of 1 kN.

-

Dr Oriol Gavaldà Diaz "Micro and nanomechanical testing of ceramics and composites"

Abstract: New structural materials rely on the micro- and nanoscale design of their microstructure to achieve the desired performance. A classic example of this can be found in long fibre reinforced composites used in aerospace, automotive or energy generation, where fibre-matrix interfaces are customised to achieve the desired strength and toughness. However, understanding the properties of these nanoscale features and their effect to the bulk failure is challenging. In this talk, I will be presenting the small-scale testing (from micro to nanoscale) that we have developed over the recent years to better understand the failure of materials and allow the design of new microstructures. I will show how we are able to test a variety of composites and ceramics and obtain nanomechanical properties such as toughness, strength and friction of fibre-matrix interfaces.

Bio: Dr Oriol Gavaldà Diaz is lecturer in the department of materials at Imperial College London (from January 2024). Oriol obtained his PhD working within the Rolls Royce University Technology Centre (UTC) in manufacturing at the University of Nottingham, looking at the behaviour of ceramic composites during a material removal process. Before re-joining the University of Nottingham as a transitional assistant professor, Oriol spent over three years as a postdoctoral research associate in the Department of Materials at Imperial exploring and developing a variety of micro- and nano-mechanical testing techniques. Currently, his main interests involve understanding the failure of materials via small scale testing (micro and nano) and advanced characterisation techniques to feed the design of the new generation of ceramic and composite materials.

We would like to thank Oriol once more for the lecture given on 10th January 2024 which was well atteneded as part of our Next Generation Fibre-Reinforced Composites (NextCOMP) Invited Lecture Series.

The recorded event is available on YouTube (0BnDTcFOruY) 51:33 min

-

Composite materials with Richard Trask - "Crusher" jelly & spaghetti example

Ever wondered what we mean by composite materials? 🧱 🧪

Professor Richard Trask, from University of Bristol School of Civil, Aerospace and Design Engineering tells us all using spaghetti and jelly!

Originally posted on Instagram 1st December 2023 by @bristolengineering

Also posted in LinkedIn by University of Bristol Engineering LinkedIn

This short video is also available on YouTube (RbH_XSLbuv4) 1:01 min

-

Dr Frédéric Laurin "Determination of the longitudinal compressive strength of some laminated composite materials using various classical and innovative tests"

Abstract: The present study proposed a critical analysis of the available existing tests in order to determine the longitudinal compressive strength of various unidirectional plies. The (i) standard compressive tests on uni-directional (UD) plies, (ii) additional bending tests on UD plies and (iii) an alternative tensile test on a specific lay-up that fails by fibre kinking were considered for different composite materials. The composites considered are (i) a classic aerospace carbon/epoxy material with standard ply thickness, (ii) another carbon/epoxy material with thin plies in order to study the effect of ply thickness on the strength and finally (iii) a carbon/thermoplastic material to highlight the role of the matrix on the strength studied. All these tests were highly instrumented in order to accurately determine the failure scenario and to ensure that the relevant failure mode was obtained.

In order to analyse such tests (compression, tension and flexure), a micromechanical model, associated with a damage model defined at the ply scale, has been proposed. It has been shown that the variation in the longitudinal compressive strength obtained at the UD ply scale for tensile and flexure tests is consistent when the fibre kinking is considered at the microscopic scale, which appears to be the relevant scale of analysis. In addition, the influence of the position of the plies through the thickness has also been considered for compression tests and can again be explained by the use of a micromechanical modelling.

We would like to thank Frédéric once more for the lecture given on 22nd November 2023 which was well atteneded on our first Next Generation Fibre-Reinforced Composites (NextCOMP) Invited Virtual Seminar Series.

The recorded event is available on YouTube (-wTUgYPkAJE) 57:05 min

-

Dr Iheoma Nwuzor "Promoting the future of innovative sustainability in composite materials for environmental impact reduction"

A full day of presentations were recorded for the 2023 Bristol Composite Institute (BCI) & National Composites Centre (NCC) Annual Conference - Composites of the Future: Tomorrow’s Materials and Applications, a joint event on the 16th November 2023 held at the Wills Hall Conference Centre in Bristol. The event featured a wide breadth of subjects including technical talks on the subjects of Ceramic Matrix Composites and Future Structures. In the Sustainable/Natural Materials technical presentations section, NextCOMP Team member Dr Iheoma Nwuzor presented her talk, focusing on sustainable composite materials to a large audience of ca. 200 people including 60+ industrial attendees.

-

Prof Leif E. Asp "Realisation and performance of carbon fibre based structural battery composites"

The 2023 NextCOMP Annual Lecture was delivered by Professor Leif Asp on 23rd August 2023, who is a member of the External Advisory Board for NextCOMP. This talk introduces one type of structural battery composites made from carbon fibre reinforced electrodes. Here, the negative electrode is made from PAN-based carbon fibres distributed in a structural electrolyte [1], where the carbon fibre performs three functions: acting as reinforcement, active electrode material (hosting lithium) and electron conductor. The positive electrode also utilises carbon fibres in its construction. By coating a lithium iron phosphate (LFP) rich layer onto the fibre surface the fibre acts as current collector and reinforcement. The electrodes are separated by a thin veil and impregnated by a structural electrolyte.

The effects of lithiation of the carbon fibre negative electrode on the mechanical performance of the structural battery composites are presented and discussed in depth along with manufacture and performance of the positive electrode and the structural battery composite full cell.

We would like to thank Leif once more for the lecture which was well received by all those who attended in-person and virtually.

The recorded event is available on YouTube (keZFfIbpR9U) 46:39 min

-

We can measure the dilation angle of polymers!

The experimental characterisation of dilation angle of polymers is fundamental to the understanding their compressive performance. In conjunction with a journal article in Polymer Testing a snapshot video of the study carried out by Dr Gustavo Quino and the Team can be found on YouTube (kKQ6c2ByXQ0) 00:29 min.

-

Arresting propagating kinkbands: Failure mechanisms under longitudinal compression of carbon-boron fibre hybrids

Dr Torquato Garulli presented at the 11th International Conference on Composite Testing and Model Identification [CompTest 2023] held in Girona, Spain between May 31st – June 2nd 2023. The event was hybrid and the recordings and slides of the presentations for the conference can be found in the University of Girona's Repository (Handle 10256/23104).

Direct link to Torquato's abstract, slides, and presentation from CompTest 2023

The recorded event is also available on YouTube (6dgWVSbl-tU) 16:16 min

-

Aree Tongloet "Investigation of the compressive behaviour of carbon/glass fibre hybrid composites with 4-point flexural test"

Aree Tongloet showcased the work carried out during her PhD at the Bristol Composites Institute Doctoral Research Symposium 2023 held on the 4th April 2023.

The recorded event is available on YouTube (k9N3apCi--0) 4:11 min

-

Dr Francisca Martínez Hergueta "Impact Response of Automated Fibre Placement Advanced Placed Ply Composites: An Experimental and Numerical Study"

Abstract: Low velocity impact tolerance is a major concern in the design of critical aerospace structures. Conventional composites consisting of laminated unidirectional plies possess poor impact tolerance, due to the propensity of their constituent plies to delaminate when subjected to dynamic out-of-plane loading. The resultant damage can significantly affect the residual strength of a composite. Alternative laminate architectures, e.g. 3D-wovens, non-crimp fabrics, and z-pinned composites, contain through thickness reinforcements which improve their out-of-plane response. However, the fiber crimp and fiber breakage introduced during the manufacture of these composites negatively impact their undamaged in-plane mechanical properties. A novel preform method known as Advanced Placed Ply preforming (AP-PLY) makes use of Automated Fiber Placement (AFP) technology to produce quasi-woven composites. AP-PLY laminates are more impact tolerant than conventional angle-ply composites, but retain the latter's excellent in-plane strength and stiffness.

We would like to thank Francisca once more for the lecture given on 2nd November 2022 which was well received by all those who attended.

The recorded event is available on YouTube (5zhM6XFrDQ4) 40:45 min

-

Professor Russell Varley "From precursor to the composite: How new carbon fibre and its composites will contribute to a more sustainable future"

The 2022 NextCOMP Annual Lecture was delivered by Professor Russell Varley on 3rd August 2022, who is part of the Leadership Team at Carbon Nexus and an invited Academic Partner with NextCOMP. Carbon Nexus works across the entire carbon fibre value chain, from spinning the precursor to producing carbon fibre tow, and of course, the carbon fibre composite. Carbon Nexus' mission is to work at the intersection of academia and industry to better understand the science and engineering of carbon fibre production and to work with industry partners to transition research into reality. This talk introduces the Carbon Nexus research facility and describes in detail the carbon fibre production process from the precursor to the carbon fibre, with specific emphasis upon the requirements for improved compression. Highlights of Carbon Nexus' recent achievements in developing a new generation of carbon fibre and its composite materials is discussed and importantly how they will contribute to creating a more sustainable future.

We would like to thank Russell once more for the lecture which was well received by all those who attended in-person and virtually.

The recorded event is available on YouTube (ihprZsUsrww) 54:44 min

-

NextCOMP researcher Dr Laura Rhian Pickard features in a video series launched by Bristol Composites Institute

Laura's film explains how, in NextCOMP, we are taking inspiration from naturally occurring hierarchical composites to design a new generation of composites which will perform better in compression.

-

NextCOMP Bristol researchers create film for Bristol Composites Institute Annual Conference 2021

The NextCOMP University of Bristol team members have created a film giving an overview of the project and some of their research. Attendees of the BCI Annual Conference 2021 will be able to discuss the research with the NextCOMP team at a dedicated interactive session during the event. It is an excellent opportunity for industry and academics to find out more about NextCOMP from our researchers.

BCI Annual Conference 2021 "Composites for Future Resilience"

BCI members on "NextCOMP: A full scale redesign for compression" YouTube (H1_vaMl0Mjc) 4:14 min

-

New lightweight materials inspired by nature | Prof. Silvestre T Pinho | TEDxUniversityofStrathclyde

Prof Silvestre Pinho presented a TEDx Talk on the subject of New lightweight materials inspired by nature as part of the series at the University of Strathclyde. The talk discusses how bioinspired materials are one of the vital keys to unlocking a more sustainable future not just for humans but for the whole planet.

-

Professor Veronique Michaud "Composites for a More Sustainable Future... Tough, Healable, Recyclable?"

The inaugural NextCOMP Annual Lecture was delivered by Professor Veronique Michaud on 8th July 2021, who is a member of the External Advisory Board for NextCOMP. She has many years of experience in composites and elevating research ideas into commercial products. The lecture was held virtually with ~70 attendees from around the world, the talk was informative and enjoyed by all with an insightful questions and answers session at the end.

The recorded event is available on YouTube (yYq4hQwG5AI) 43:45 min

-

Next Generation Fibre-Reinforced Composites: A Full Scale Redesign for Compression - Project Overview

NextCOMP: A full-scale redesign for fibre-reinforced composites, YouTube (v6lwX54Be_s) 5:23 min